The food industry Product Lifecycle Management puzzle

- The food industry is under pressure.

Consumers are demanding more detailed information on ingredients. They want new products faster in line with trends on clean label, health, vegan and other. Besides that, the supply chain for food companies is getting more complex with ingredients sourced across the globe and handled, composed and processed in different countries before it arrives at the factory for being used in the consumer product. On top of that regulations by governments and requirements from retailers are getting stricter. The availability of detailed supply chain data and high-quality product information is essential. Finally, the financial stakeholder would like to see revenues while margins are under pressure due to the competition and the power of retailers.

- The product development process is complex.

With that pressure in mind it would be helpful if the development and introduction of new products is an easy, quick and smoothly process. However, the opposite is true.

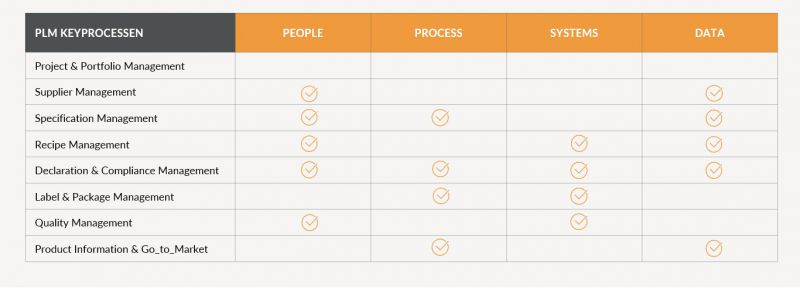

The development of a food product is a long and complex process. It includes multiple phases, many different departments and internal/external stakeholders, a huge amount of data to store and maintain. Zooming in, the following key processes can be described as part of the whole process.

- Project & Portfolio Management

- Supplier Management

- Specification Management

- Recipe Management

- Quality & Safety

- Declaration & Compliance Management

- Label en Package Management

- Product Information & Go_to_Market

- The use of “spaghetti” systems

How to run and control these process ? How the handle and maintain all related data ? This is where the IT part mostly starts. Starting at department level software systems are brought in to handle a certain piece of data or certain part of the process. Software systems to keep track on NPD projects, suppliers, recipe development, supplier data, raw material specs, allergen’s, packaging, labels and more. Systems designed as ERP, PDM, PLM, QMS, PIM. Not to forget Excel as the most used piece of software to keep track. All designed for just a part of the job. Individual systems with data related to each other but not connected. Like a bowl of spaghetti. Resulting in isolated data with a high-risk for error’s and very time consuming manual data transfer both internal and external.

- The PLM Promise

This is where the Product Lifecycle Management (PLM) promise comes in. The Gartner IT Glossary describes Product Lifecycle Management (PLM) as a philosophy, process and discipline supported by software for product management during the phases of their life cycle, from concept to retirement. CIMdata explains; Product Lifecycle Management (PLM) combines data, processes, systems and people into an end-to-end solution for the development and marketing of products. Important to know is that PLM is not a technology. It is a business approach to improve the creation and management of all information related to the product throughout its lifetime. Typical measurable advantages when implementing the PLM principles:

- Reduction of time to market,

- Elimination of inefficiencies, risks and costs

- Improved data and product quality.

- The PLM puzzle

Now the puzzle starts. How can the food industry benefit from the PLM advantages and improve business performance ?

First of all discover the current status of your PLM process. Review Each of the key process on the key factors of PLM, the status and integration of data, processes, systems and people. Are the process to initiate and maintain the data clear ? Who are responsible ? Permissions to access or modify data ? Which functionality domain is used to store data ? Systems in use ? What are all our data objects ? Multiple versions of truth ? Manual efforts ? It will give insights in the inefficiencies, risks and opportunities of the current setup in relation to the entire product lifecycle.

Secondly it all about how we can solve the gaps and get more out of our existing systems. If you want to benefit the PLM advantages, it is not necessarily about selecting a full new PLM software system to replace the isolated and fragmented spaghetti setup. It is about fixing the missing parts. Centralize the responsibility and storage of data, integrate systems to takeaway manual data transfer, reduce the number of data objects, extend existing systems, create best of breed setup and more. Much can be done to take the pressure away and to benefit from the PLM advantages and improve business performance.